The SureColor Fabric series represents a revolution in textile printing technology. Equipment has been designed from the ground up to ensure superior quality, performance, and reliability when imaging on cloth, garments, and merchandise. The F2000 is a Direct To Garment (DTG) printing platform for work involving cotton based shirts, caps, bags, and promotional items. Prints can be made to pre-cut fabric or directly onto a finished garment with a heat press then used to 'fix' the dye. It enables production of customised and value-added goods with high impact and good wash/wear durability. Unique to the Epson solution, the printing platform and ink have been developed together. This integrated approach not only ensures exceptional image quality with reduced running costs, but also enhanced mechanical durability with a reduced maintenance burden. The system is quick to install, easy to operate and offers fast, flexible production for low volume applications.

The SC-F2000 uses Epson UltraChrome® DG ink along with an advanced PrecisionCore™ print head. The ink provides a significantly enhanced colour range with high brightness, formulated for easy fixing with a flexible and durable finish. The head provides improved resolution and enhanced reliability with precise dot sizing and placement for smooth predictable colour with minimised bleed and ink consumption.

FEATURES AT A GLANCE

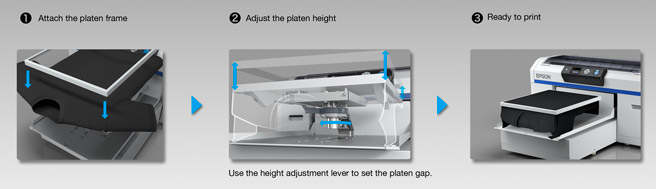

- High Productivity – easy platen loading with auto height sensing and simple adjustment. Will print a t-shirt in as little as 44 seconds.

- High Flexibility – supports fabric up to 25mm thick with platen options available to support print areas up to 406x505mm. Ships in a choice of two configurations; High Speed 4C for work with light coloured fabrics OR 5C with additional White ink to suit light and dark coloured fabrics.

- Outstanding Print Quality – Advanced Epson PrecisionCore™ Print Head, LUT and ink technology enable exceptional image quality. Prints are consistent and predictable with high brightness, high elasticity, high wash/UV durability, and full Oeko-Tex conformity1

- Low Operational Cost – uses minimum ink to achieve maximum colour with a choice of cartridge sizes available to suit different production levels and cost-per-print requirements. NEWLY RELEASED firmware enables optional manual cleaning for minimum wastage with minimum effort.3

- Compact and Convenient – features a small footprint with all-front-loaded consumables and a large colour LCD control panel with in-built help. Will accept print jobs from either a PC or USB storage device2

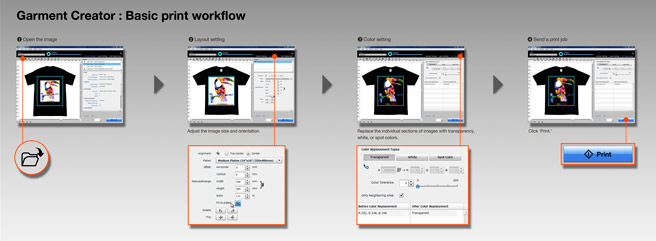

- Easy to Install & Operate – Quick to set-up and comes supplied complete with Epson Garment Creator software. Additional software compatibility Info

Quality Results

The SureColor F2000 has been designed for custom in-store printing and low volume commercial applications. It features a solid chassis with high precision head and platen movement. It incorporates Epson's advanced PrecisionCore™ Thin Film Print head with micro-fine nozzles that support resolutions up to 1440x1440 dpi with outstanding dot uniformity and pin-point positional accuracy. When an image is sent to print, it is processed through a customised Look-Up-Table that selects the precise amount of each ink before the printer applies it quickly and evenly for a superior image with reduced production costs.

Epson's new UltraChrome DG Ink supports fabric with a 50% or greater cotton content. It features an enhanced Gamut and dMax for superior value-adding on garments and merchandise. It adheres well and fixes easily to produce images with a low tack finish that have good UV/wash durability. The ink has reduced toxicity for simpler handling and a safer work environment. When applied to cotton fabrics both the ink and Epson’s Pre-Treatment liquid conform to the latest Oeko-Tex Eco Passport® standard and are certified safe for use by adults, children and babies1.

Easy to Install and Operate

Direct To Garment printing replaces the complex, messy and time consuming process of screen printing with a fast and flexible digital solution. Artwork can be designed and edited on a PC using a range of readily available drawing and photo editing programs before being printed directly to one, two or a hundred pieces of clothing. The Epson F2000 is quick and easy to set-up and has been designed to be driven by an operator with basic textile and PC skills. The printer can be purchased in two configurations; 4C Colour Only, or 5C Colour with White. The 4C model is designed for high speed work on light coloured fabric. The 5C configuration enables more flexible production with additional white ink that can either be applied as a separate colour, or as a base upon which CYMK ink is applied when working with garments manufactured from darker fabric.

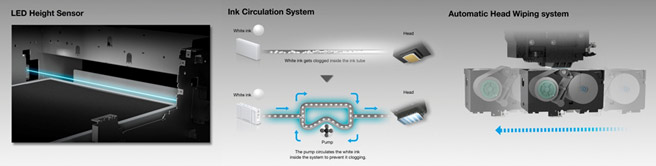

The Epson F2000 features a highly adjustable platen height that suits some of the thickest and most heavy garment types. Adjustment is simple and easy and the machine incorporates an optical (LED) sensor to help protect the mechanism against incorrect loading. It features a high degree of self-cleaning and self-maintenance to help minimise the amount of operator training that is required while ensuring superior, consistent results with reduced downtime, and ink wastage. It features a large front panel colour LCD with an easy to use menu system and inbuilt help. It ships complete with Epson Garment Creator software that enables easy image resizing, placement adjustment, colour management and job costing. The software facilitates rapid printing of ready-made artwork either directly or via USB storage. The printer incorporates a front panel USB socket that can be accessed by the PC for file storage + retrieval or from the printer for fast PC-less printing2.

Flexible and Economic to Run

The F2000 will print a full sized T-shirt in as little as 44 seconds while simple logos and graphics are even faster. It comes with a removable platen that supports standard adult t-shirt sizes as well as many common merchandise items. It has been designed for one man operation with easy loading and unloading. Optional additional platens can be purchased separately for work environments requiring higher volume production with separate preparation, pre-treatment and/or fixing stations. Platens are available to suit oversized garments, child sizes and even sleeve printing. Platen height setting is easy and the printer incorporates an optical sensor for accurate checking.

The F2000 has been designed to ensure the minimum amount of ink is used on each print job while achieving optimum colour and brightness. The amount of time, difficulty and cost involved with maintenance has also been minimised. The printer incorporates a re-circulation system to reduce the sedimentation inherent with white ink and has front loaded cartridges for easy loading and replacement. It features a self-cleaning print head and a mist extraction system with consumables that are quick and inexpensive to replace. Components that require periodic manual inspection and cleaning are easy to access and the printer actively monitors performance and automatically notifies the operator when attention is required. A NEW Tube Maintenance Kit enables significant waste reduction on the 5c White configurations in return for a small amount of daily maintenance.3

1 ECO PASSPORT by OEKO‐TEX® is an international standard for the textile industry system. It enables suppliers to demonstrate that products can be used in sustainable textile production. For further information please see the OEKO-TEX web site.

2 The USB device must be FAT32 formatted and files must be processed through Garment Creator before they can be recognised by the direct print function in the printer.

3 Customers are recommended to speak with their dealer regarding cleaning and maintenance issues before purchase. Regular (daily) manual agitation of the ink cartridges is required to ensure consistent performance. In full automatic mode the printer will periodically (typically once every 3 to 9 months for colour channels and once every two to four weeks for white channels) request the user remove ink cartridges and insert cleaning carts to perform a full internal clean. The process must also be undertaken if the printer is not used for a period of 2 weeks or more. The cleaning process is mandatory and will result in the purging of all ink stored in the relevant channels inside the machine (remaining ink in the cartridges is preserved). With installation of the latest firmware (download available here) and selection of the optional Manual Tube Cleaning Mode the user can prevent the wastage associated with the periodic purging in return for 10 minutes of daily manual cleaning using the optional new Tube Maintenance Kit.