The SureColor F11060 is designed to support high-volume roll-to-roll production in widths from 36” to 76”. It features a heavy-duty print engine with precision media tracking and Epson’s latest printhead technology. It supports production at up to 255 m2/hr with a high-capacity ink system, a choice of 4c and 6c configurations and a new (optional) heavy-roll feed unit. Production fabric printing has never been this fast, efficient, and cost-effective.

The SC-F11060 achieves an outstanding gamut with just four inks. It uses UltraChrome DS and applies Epson Precision Dot Technology to enable output with intense, accurate and consistent colour. For those with demanding applications, it can be ordered in a 6c configuration (SC-F11060H) with two additional channels for either Light Cyan and Light Magenta, Orange and Violet or Fluorescent Pink and Fluorescent Yellow ink. The printer features automated media setup and advanced tracking for quality imaging at the fastest speeds. It supports the widest range of media and has an optional heavy feed system for rolls up to 500 kg. The printer incorporates advanced self-cleaning and printhead management for consistent output with minimal supervision and maintenance. An integrated Epson Cloud Solution PORT service provides advanced management and costing tools while enabling enhanced support and optional user self-replacement of key components including the printhead.

FEATURES AT A GLANCE

- Superior quality – incorporates four (six in the F11060H) latest generation Epson 4.7” PrecisionCore™ TFP printheads with Variable Sized Dot Technology. Uses Epson Precision Dot image processing with advanced multi-layer half-toning, optically enhanced media tracking and UltraChrome™ DS ink to enable saleable output at the highest production speeds.

- Excellent flexibility – supports media from 39 gsm or less up to 1 mm thick and 914 mm to 1950 mm wide. The standard configuration supports rolls up to 60 kg, while an optional heavy feed system supports rolls up to 500 kg1. Eco Passport compliance ensures that sublimated fabric may be used by all age groups.2

- Outstanding productivity – print 1 m2 in as little as 14 seconds with integrated drying. Flexible high-speed networking with a 155 GB buffer and integrated step & repeat support ensures efficient operation. An 80 L max (120 L in the F11060H) ink supply with auto hot-swap and high precision auto take up enables extended roll-to-roll operation with minimal attendance.

- High reliability – precision airflow management and integrated media cleaning provide an optimum production environment with minimum dust. Inkless-nozzle status sensing with auto-replacement and auto-recovery is matched with auto printhead cleaning for consistent quality with minimal wastage. A heavy-duty print engine with powerful motors and a linear motion guide carriage ensures maximum reliability and operational durability.

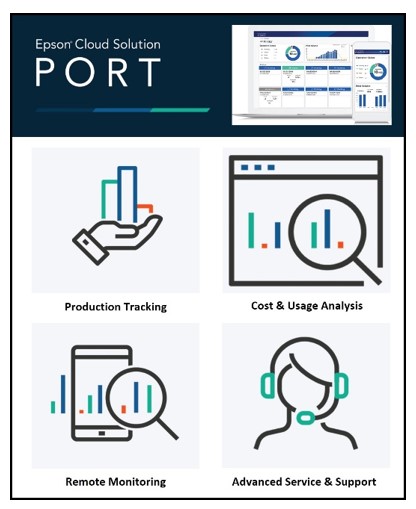

- Reduced cost – uses cost-effective box-based ink and is supplied with Epson Edge Print software. Epson Cloud Solution PORT provides advanced costing, reporting and management tools, accessible on desktop and mobile devices. CoverPlus is linked with PORT for comprehensive parts and labour cover, up to 5 years with remote diagnosis and optional printhead user self-replacement3.

EASY SET-UP & OPERATION

The SureColor F11060 squeezes a lot of performance into a relatively compact and extremely flexible package. Despite its high-capacity ink supply and heavy roll media support, it requires a relatively small operational space due to its integrated design. The printer runs off single phase 240 V power and only needs two 16 A sockets1. While an air-conditioned, humidity-controlled and low-dust environment is recommended for optimal output, the printer can also be installed and used in warehouse environments. The printer produces minimal odour and operates at less than 60 dB of noise.

Labour is usually a significant cost when it comes to fabric production. The SC-F11060 supports single operator media loading with an integrated lifter, dual front/back platen locks and feed control. Operation is made easy with the large 9” touch panel control with integrated help and online video assistance. It features an industrial-style signal light and a platen window with in-built lighting. When printing, it requires very little attention and can be managed remotely via PORT. The optional heavy roll feed system enables operation with rolls up to 500 kg and 500 mm diameter.1

SUPERIOR IMAGE QUALITY

The SC-F11060 features four of Epson’s latest PrecisionCore Thin Film MicroPiezo printheads (six in the SC-F11060H). Each head incorporates four elements that enable high-speed imaging with outstanding resolution. The heads support Variable Sized Droplet Technology (VSDT) for fine gradation and optimum colour with minimum consumption. The heads are driven by advanced Epson Precision Dot Technology that uses a new multi-layer halftone to reduce grain and banding. Saleable production can be achieved at maximum pass rates.

Epson UltraChrome DS ink supports production of a wide range of goods, from material and clothing, to soft signage and banners. It even supports hard signage, photo and custom merchandise applications. Using a simple CYMK set, it achieves gamut levels equivalent to competitor products with six or more colours. The black ink features a high-density formulation for enhanced colour with a more neutral tone. For enhanced output, the SureColor F11060H supports 6c operation, which can be configured with additional LcLm ink for fine gradation, smooth skin tones and outstanding photo reproduction. Alternatively, it can be configured with OrVi ink for an expanded colour gamut, or fluorescent FyFp ink for bright sportswear, safety gear and eye-popping soft signage 4. The ink adheres quickly, transfers smoothly, provides excellent UV and wash-fastness. It meets AZO requirements and when applied to polyester fabrics it adheres to the latest Oeko-Tex Eco Passport® standard, ensuring safe use for adults, children and babies 2.

The printer comes with Epson Edge Dashboard software that enables simple and easy management. The application provides access to downloadable EMX files that facilitate rapid setup with common media types. The print carriage also incorporates a high-resolution RGB camera that helps automate setup with custom media.

FAST & COST-EFFECTIVE OPERATION

The SureColor F11060 has been designed to produce high-quality output, on a wide range of media. An integrated, double-sided dryer with adjustable temperature control ensures the optimal mix of conductive and air-blown heat, for high-speed operation with the heaviest ink loads. Active multi-point media tracking enables smooth and reliable operation, with accurate image sizing and placement.

The printer features high-speed networking and a large buffer memory. Smart image processing with on-board job connection, step & repeat, increases production efficiency while saving repeated file transfer. The high-capacity bulk ink system uses cost-effective ink that ships in a choice of 3 L or 10 L boxes that are quick and easy to load. The system incorporates dual ink sets with automatic hot-swap, and is paired with a high-capacity 4 L waste facility. A high-precision auto take-up works actively with the feed system to enable roll-to-roll production with outstanding tension consistency and parallelism. The operator can even instruct the printer to include key production data at the end of each job to assist with subsequent sublimation. When used in conjunction with a quality calendar heat press, it enhances both production efficiency and output quality.

HIGH DURABILITY WITH LOW MAINTENANCE

The SC-F11060 has been designed to support continuous and reliable operation. Careful airflow management and an integrated media cleaner help exclude dust. Nozzle status monitoring is paired with intelligent print quality management for extended production without interruption or dot loss. Missing nozzles are automatically masked and/or recovered, while a high-capacity fabric head wiper engages periodically, to ensure dependable operation with minimal maintenance.

This printer features a heavy-duty chassis that has integrated locking mechanisms to ensure a solid and stable production platform. Powerful DC motors are matched with a print carriage mounted on a linear motion guide for smooth and reliable operation without the need for regular greasing. Built-in sensors prompt the operator when maintenance is required with on-screen help and online video guidance.

Service is often a significant issue for production equipment, particularly when it comes to fabric. Breakdowns interrupt workflow, while unexpected repair bills are a drain on cash flow. The F11060 can be ordered with a range of service packages that are not only flexible but provide truly comprehensive cover. If you need maximum up-time and have staff with moderate technical ability, then user self-replacement can be enabled on selected components including the printhead.3

SUPPLIED AS A COMPLETE PACKAGE

The SureColor F11060 ships with the latest Epson Edge Print Pro. The software provides a simple and effective tool for production of quality output. While traditional RIP applications are hampered by generic drivers and imaging limitations, this software was developed by Epson for Epson printers and provides access to the full power inherent in the equipment. It features an uncluttered interface with advanced on-screen visualisation and an Adobe™ Postscript® engine that supports PS, EPS, PDF, TIFF, JPEG and PNG files. It incorporates basic functions such as copy, position, and trim, along with advanced colour correction, nesting and tiling. When used with an F11060H, it even allows fluorescent ink to be incorporated as a continuous tone, in addition to traditional spot application.

The SC-F11060 incorporates integrated support for Epson Cloud Solution PORT. This free service provides operators advanced monitoring, management, and costing facilities. Information is accessible from the desktop as well as mobile devices (Android and Apple); data at your fingertips, wherever and whenever you need it. It also facilitates enhanced support for up-time maximisation with remote diagnosis and optional user replacement of key parts including the printhead.3

1Heavy roll media requires special handling equipment and it is not recommended that loading be performed by a single person. Heavy roll support is currently available on the feed system only, with the take-up limited to 60 kg, customers requiring greater output capacity are encouraged to contact Epson and/or their dealer. Operation with the optional heavy roll feed unit requires additional power (refer the specs tab for details). A list of compatible alternative RIP and/or workflow software can be found on this website, with information compiled from the relevant manufacturers. For details on additional product support, customers are recommended to contact their preferred software vendor directly.

2ECO PASSPORT by OEKO‐TEX® is a system by which textile chemical suppliers demonstrate that their product can be used in a sustainable textile production. Epson dye-sublimation ink is certified by the ECO PASSPORT. This is an international safety standard in the textile industry. It is certified to be safe for adults and children, including babies. For further information please see the OEKO-TEX website.

3After-sales support is coordinated by Epson in conjunction with our authorised reseller and service networks. Support may be restricted or limited if equipment is used outside of specification, with incorrect and/or non-genuine consumables. CoverPlus requires activation of Epson Cloud Solution PORT, agreement to the terms of supply and connection to the Internet. User self-replacement requires staff to be appropriately skilled and trained. For further details, please refer to the specs tab.

4The F11060H can be configured at set-up for CYMK plus either LcLm, OrVi, or FyFp. Once initialised, the colour configuration cannot be changed.